Home / Centrifugal Finishing Machines

Centrifugal Finishing Machines are very high gravitational forced machines specifically developed for those components which require long process times in Vibratory Finishing machines.

There are several options available — straight barrels, inclined barrels, removable barrels (for small machines), variable speeds, media parts separators, rubber/polyurethane linings, conveyors, etc.

Centrifugal Finishing Machine

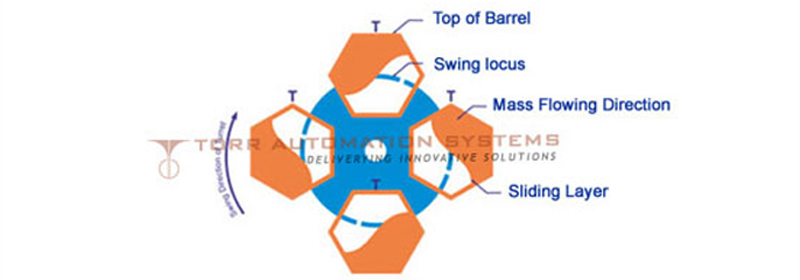

Centrifugal Finishing Machine - Twchnology Series is Composed of a number of barrels mounted on the perphery of a turret, The Turret rotates at high revolution per minute (RPM) in one direction while the barrels are rotated in the opposite direction. Parts to be deburred and finished are placed in each of the barrels, normally together with media, water and some form of compound.

Turret rotation creates a high centrifugal force of up to 50 times earth gravity, thus compacting the load within the drums into a tight mass.

The counter rotation of the barrels causes activity of this tightly packed mass. The media slides against the parts being processed, removing burrs and improving surfaces. The Abrading action during the high centrifugal force results in avery short process cycle.

The inclined axis barrels rotation generates unique SUPER-EIGHT motions, which casuses additional rubbing and polishing effect.

Achieving the impossible finishing in ULTRA SHORT TIME

Several results which were not possible so far in rotary barrels and vibratory finishing machine can now be achieved in Centrifugal Finishing Machine. Our sound experience in establishing successful vibro finishing processed & extensive trials conducted on Centrifugal Finishing Machine in our Laboratory has gained us a confidence to claim following comparison for the time taken by Rotary Barrel (RB), Iibratory Finishing Machine (VFM) and Centrifugal Finishing Machine (CFM).

Burnishing, Lustering and Mirror-Line Finishing

The raw steel with roughness of 10 micron can be improved to 1 micron in 30-60 minutes, while the conventional burnishing and lustering can be obtained in 15 to 30 minutes.

Heavy Cutting

Take 20-30 minutes for major deburring, descaling of black skin of casting and forging, finishing of tiny parts. The cutting action is similar to center less grinder.

Elimination of Entanglement and Distortion

No distortion found in thin plates (up to 0.4 mm thick), Small thin flat parts, which easily stick to each other and used to be impossible to process can be perfectly processed e.g. valve reeds etc.

| Model | Total Capacity (Ltr.) | Floor Space L x W x H |

Motor HP | PU Lining Thickness (mm) |

No. of Barrels |

|---|---|---|---|---|---|

| TCFM 10 | 30 | 850 x 760 x 1150 | 1.5 | 10 | 4 |

| TCFM 30 | 30 | 1200 x 1150 x 1350 | 3.0 | 10 | 4 |

| TCFM 60 | 60 | 1200 x 1450 x 1650 | 5.0 | 10 | 4 |

| TCFM 100 | 100 | 2000 x 1600 x 1900 | 10.0 | 10 | 4 |

| TCFM 160 | 160 | 2250 x 3200 x 2300 | 10.0 | 15 | 4 |

| TCFM 200 | 200 | 2270 x 3300 x 2700 | 15.0 | 20 | 4 |