Home / Mass Finishing Solutions

Mass finishing is a group of manufacturing processes that allow large quantities of parts to be simultaneously finished. Mass finishing solutions are used for various applications like De- burring, edge radius, De-scaling & De-rusting, Ra value improvement, Degreasing, Mirror finishing, Brightening, Burnishing, Polishing, Pre plate finishing & prepare parts for further finishing, or break off die cast runners. These involve the use of a cyclical action to create grinding contact between surfaces. Sometimes the work pieces are finished against each other; however, usually a finishing medium is used. Mass finishing can be performed dry or wet; wet processes have liquid lubricants, cleaners, or abrasives, while dry processes do not. Cycle times can be as short as 10 minutes for nonferrous work pieces or as long as 2 hours for hardened steel.

Torr dreams of a quality future environment by technological progress. As a pioneer of Mass finishing solutions, we are ready to meet customers’ needs with the most advanced technology.

Advantages of MASS Finishing Systems:

Up to 80% reduction in labour involvement.

No batch to batch variation (if required).

Flexibility to process variety of components.

Fully controlled process.

Higher production.

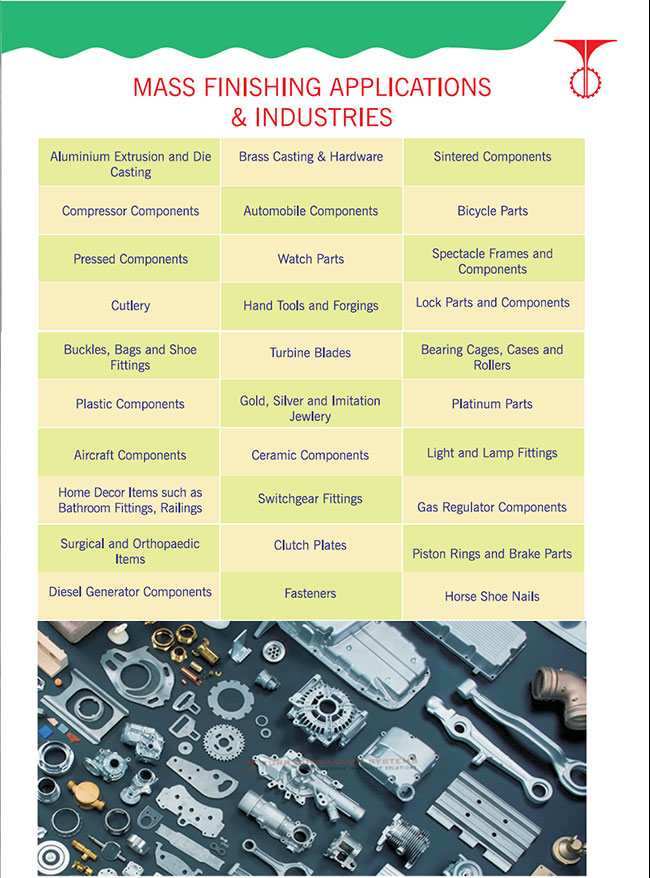

| Aluminium Extrusion and Die Casting | Brass Casting and Hardware | Sintered Components |

| Compressor Components | Automobile Components | Bicycle Parts |

| Pressed Components | Watch Parts | Spectacle Frames and Components |

| Cutlery | Hand Tools and Forgings | Lock Parts and Components |

| Buckles, Bags and Shoe Fittings | Turbine Blades | Bearing Cages, Cases and Rollers |

| Plastic Components | Gold, Silver and Imitation Jewellery | Platinum Parts |

| Aircraft Components | Ceramic Components | Light and Lamp Fittings |

| Home Decor Items such as Bathroom Fittings, Railings | Switchgear Fittings | Gas Regulator Components |

| Surgical and Orthopaedic Items | Clutch Plates | Piston Rings and Brake Parts |

| Diesel Generator Components |